Technology

Introduce Technology For Keywords

-

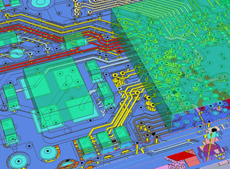

Advanced design technologies

Superior pattern design by our certified (JPCA level one and two Certified Printed wiring Designers) design engineers.

-

Short delivery shift

Design support, using two shifts, 24 hours a day, 365 days a year.

-

Impedance control wiring

With simulations and comunication with the manufacturing site, we are able to design patterns with emphasis on impedance control.

-

DFM verification

With almost 300 design rules used in designing, we are able to detect problematic processes and improve prior to manufacture, thus cutting down the number of prototypes needed.

-

EMC design services

Using 39 chapters of Electronic rules regarding EMC, SI, PI, etc, we are able to instruct EMC design effectively.

-

Silicone free

Type zero (0) contains no Siloxane.

-

Environmental conservation / cost-reduction

Repairs to Magic resin (reforming), recycling of the carrier base material, and shaping of the resin to customer demands.

-

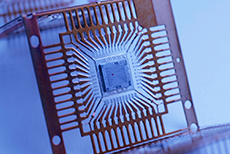

Response to a high-speed signal

With our Lamination technology that creates even thickness on each layer, and our conductor processing, we are able to create a highly stable impedance controlled product.

-

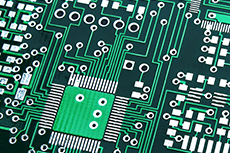

High density

High density boards utilizing Laser drilled vias, Fill-plating, stacked vias and build-up lamination technology.

-

Thinner boards -1

Ultra-thin multi-layered build-up boards utilizing ultra-thin cores, or coreless boards.

-

Thinner boards -2

By combining flex boards and build-up technology, our Flex rigid boards require no connector boxes, thus saving space, and with laser drilling, we can achieve thinner, smaller boards.

-

Downsizing -1

Achieve downsizing with the latest laser drilled via shaping, and improved fine-pitch wiring density

-

Downsizing -2

By combining flex boards and build-up technology, our Flex rigid boards require no connector boxes, thus saving space, and with laser drilling, we can achieve thinner, smaller boards.

-

Connection reliability

By utilizing the board edges with half-through hole technology, we increase the area and adhesion of solder, thus providing better connectivity.

-

Conserving space

By utilizing component mountable cavities, we are able to lower the board's height and save space.

-

High durability and high reliability

Experienced in supplying boards requiring high durability and high reliability in our multi-layer through-hole boards for the automotive, medical, and industrial (robotics) industries.

-

Multi-pin densification

Using laser processing and semi-additive patterning, we can provide higher pin count with higher density.

-

Small quantity, large variety

We have solutions for your small quantity large variety issues.

-

Prototype short delivery

Capable of very short delivery times.

-

Mass production

Open to suggestions such as Overseas production or VE, VA that will increase competetiveness.

-

Security

We offer the service and support that only a trusted PCB maker can offer.